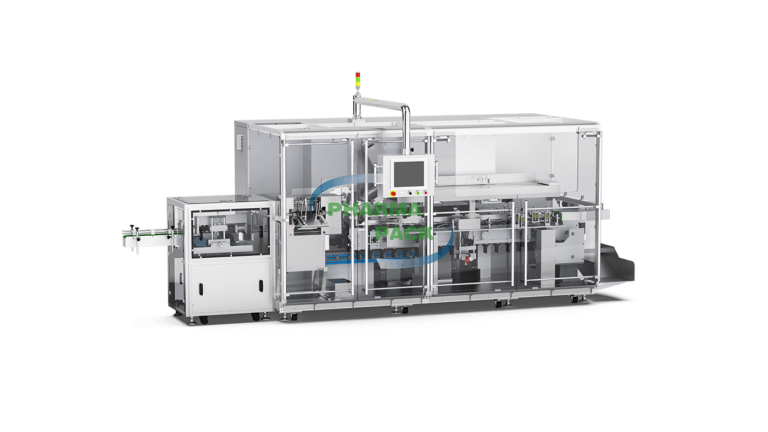

he product is placed on the in-feeding conveyor manually or automatically. After the detection of the product, the product coming sensor on the conveyor will send the signal for sucking out the carton and feeding onto the conveyor, pre-opening it while lift down.

2. Carton is put on the station while the leaflet is conveyed to the insertion point. The leaflet will be inserted into the carton together with the product. Then the carton will be printed on the flap when it passes through the station.

3. The carton with inserted product and leaflet will be conveyed into a gear-shape conveyor mechanically, and be tucked into from the point till finished. Then flap will be coded.

4. Defective product will be detected and rejected